Advanced Machine Guarding Solutions, designer and manufacturer of safety guarding solutions for various applications, collaborated with Helioz Technologies to implement Helioz’s Onshape Integrator for its Panels.

About Advanced Machine Guarding Solutions

Advanced Machine Guarding Solutions is 35 years experienced, knowledgeable, reliable, and local safety

guarding partner that helps companies easy to design, assemble and customize safety guarding solutions.

It offers customers a different experience when designing, purchasing, and installing perimeter guarding,

ensuring customizable and flexible products are designed with the major electronic safety components in

mind.

AMGS’s panels and doors can be easily made to meet specific safety guarding needs, with the possibility to

add additional safety devices like light curtains, area scanners, safety interlock switches, and others. All

products meet or exceed ANSI or ISO standards and are attentively created by experienced machine and robotic

designers with an extensive business background.

The Challenge

One of the challenging things for companies is to offer customers a simple and easy process of purchasing customized products and, at the same time, offer interaction with the product before placing an order. Having a simple solution that covers all those needs can boost business efficiency and streamline operations and processes. Having a configurator gives customers a visual interface where they can change various attributes and view a fully personalized product designed to their specifications. By giving customers a customizable product, brands can engage directly with customers and offer an immersive and engaging process that increases conversion and sales.

The Solution

While having that in mind, AMGS and Helioz collaborated to unite the product

configurator, 3D preview, 2D drawing, and Bill of Materials field into a single portal seamlessly integrated

with AMGS’ website to ensure products purchase faster, easier, and much simpler.

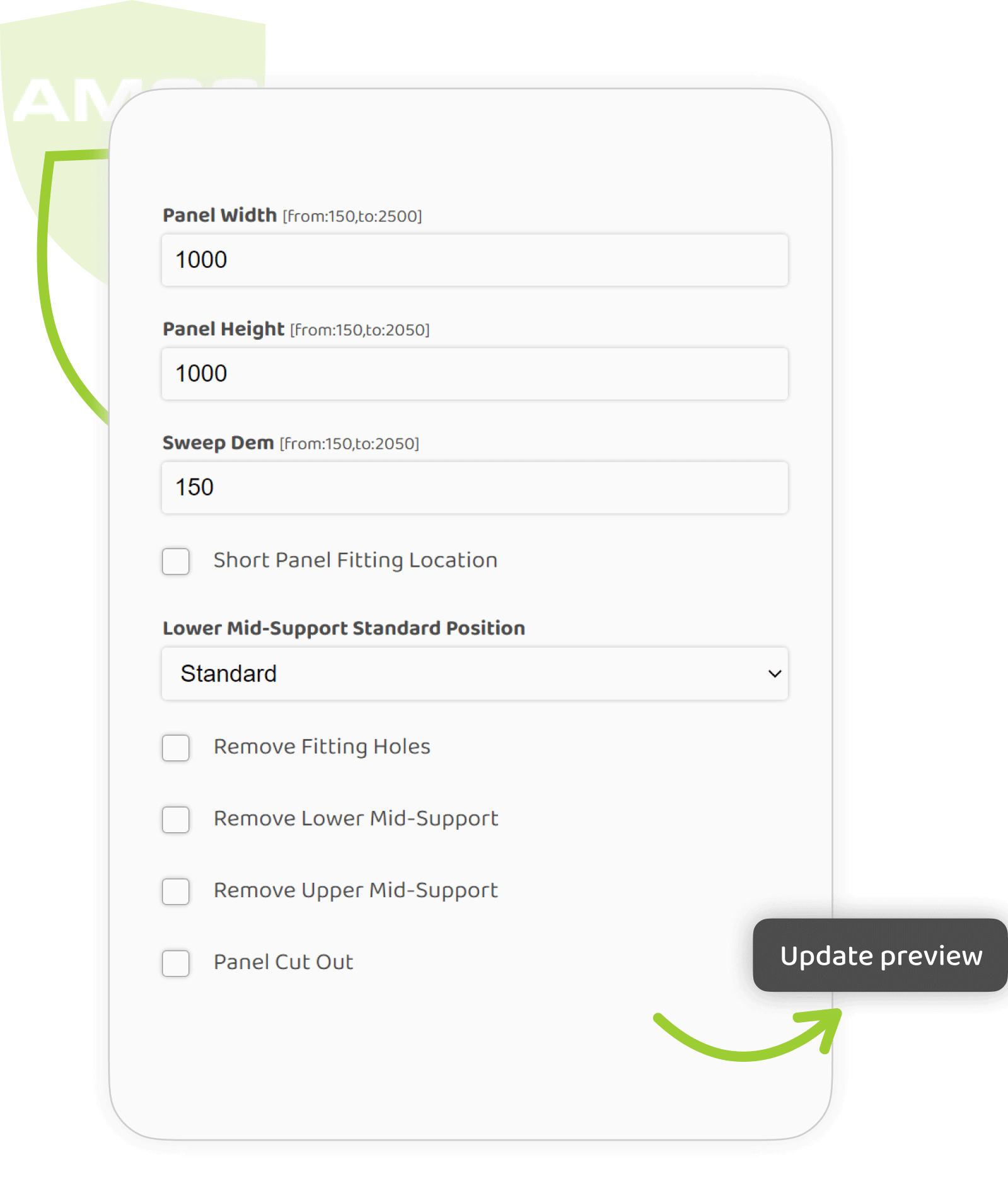

Visitors of AMGS’ configurator portal first configure a panel by selecting desired options. Configurator

logic is powered by Onshape, whose logic architecture is improved with interactions between options.

Configurable products drive higher engagement than their static counterparts. Seeing how different product

options appear in front of them is also a powerful psychological incentive for customers who want customized

experiences and products.

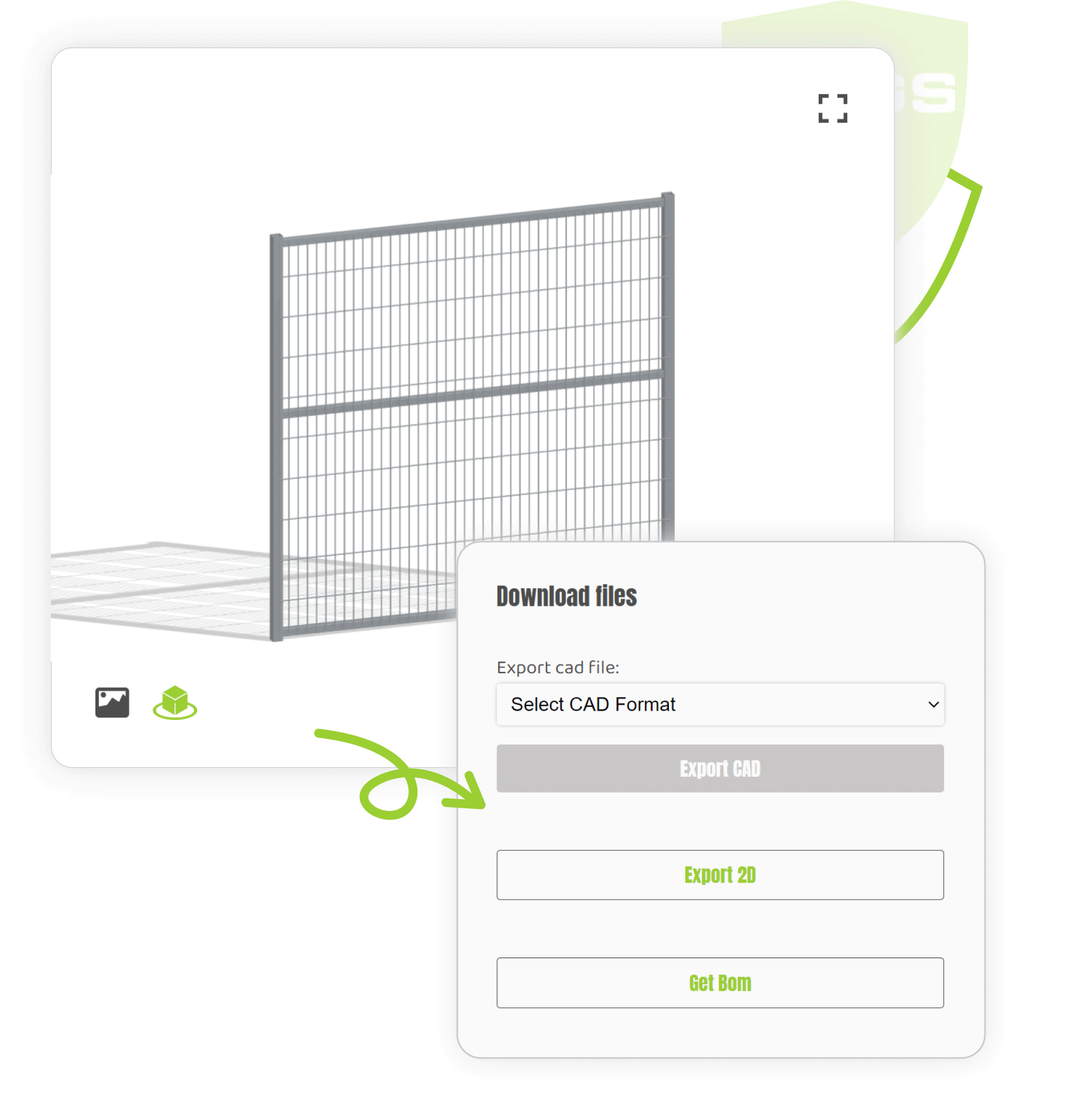

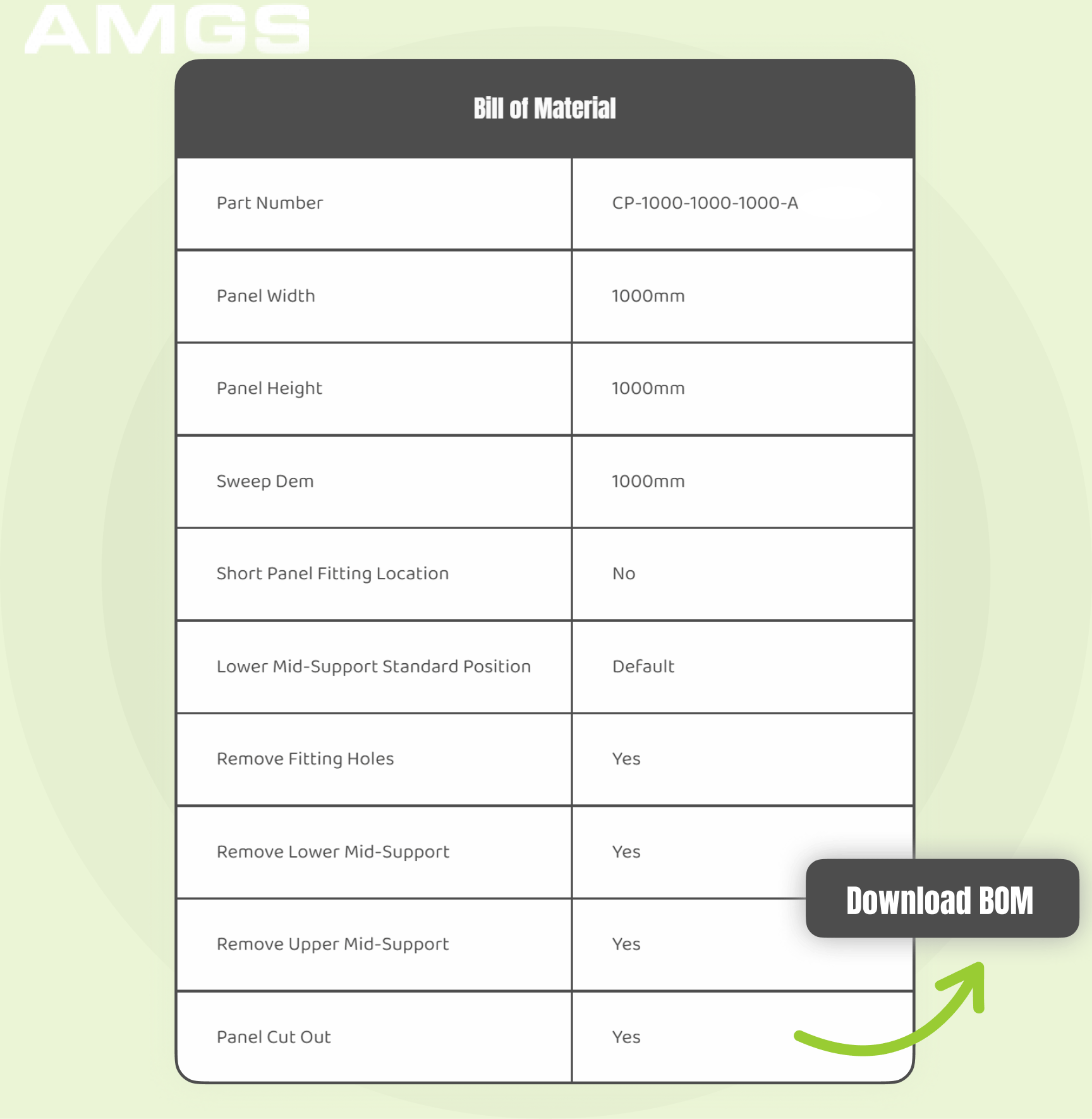

The configuration process results in a unique AMGS configuration number being generated and listed in the

Bill of Materials field. With Helioz’s 3D viewer functionality, customers can visualize every change during

the configuration process in real-time and download a final model in various CAD formats.

Finally, once the product is identified, its detailed specifications are collected in the downloadable

Bill of Materials table and are available for product selection review.

Since tracking end-users configurator and CAD activities can give AMGS team potential leads, Helioz team

prepared and implemented a Guest Form. Before downloading a BOM field, 2D drawing, or CAD, the end-user

needs to populate Guest Form by entering personal information. Using this approach, AMGS receives weekly

reports to track configurator activities and receives separate email notifications for each activity.

AMGS has reported that configurator implementation is a big step forward in business success and will

help the company improve customer experience and accelerate customer acquisition even more.

With its new solution online, AMGS’s business will benefit from the latest technology focused precisely

on the customer, and its customers will meet the best possible digital customer experience.

Project Journey

The project journey has been separated into three periods/sprints during which specific work was completed and made ready for review.

Our first step during sprint one was defining a user interface that will meet

all required needs and retain the visual identity that AMGS has already built. We have defined three main

sections of the portal where features were later implemented: configurator, preview, and downloads.

The graphical layout meets all transitions, interface animations and single micro-interaction needed. Every

sort of visual element, interaction, and animation has been individually designed and combined into the

final layout. Since user interface elements are easy to interact with, the experience during the interfacing

of a portal user can find pleasant and easy.

During the design development in sprint one, our task was also to detect configurator logic that has already

been defined in Onshape and pull it on the frontend. Along with the configurator logic, we also pulled

already prepared 2D drawings for panels and CAD formats and implemented them all on the front.

The configuration process, defined inside the Onshape project, results in a unique Panel part number. The

model of every configured part number is shown in the viewer. Product Configurator is pulled from Onshape

but adjusted with an additional experience like options interactions; when the Panel Cut Out option is

checked, its dimensions appear, and when the option is unchecked, the dimension disappears too. That is why

our Integrator, in combination with Onshape, provides a high level of user experience. The experience level

is increased even more thanks to the 3D preview of the model.

Helioz viewer is connected to the Onshape and updates the model view based on the user selections in the

Product Configurator. The 3D view allows the user to have a preview of the product with the ability to spin

the model around, zoom in and out, and see all the configured options. This allows end-users to visualize

and explore 3D models and get a realistic preview of the physical product.

During sprint two, Helioz implemented Configurator Instructions downloadable for

users to see the purpose of every configurator option. Helioz also prepared a Bill of Materials field that

collects all configured options in one place, ready to be downloaded.

This field lists part numbers of every specific configuration which AMGS created using a Part Number

Generator script developed by Helioz.

Even though it was the last one, this sprint was set for one of the most

valuable features for the AMGS business; Guest Form. Since tracking end-users configurator and CAD

activities can give AMGS team potential leads, during sprint three, the Helioz team prepared and implemented

a Guest Form.

Before downloading a BOM field, 2D drawing, or CAD, the end-user needs to populate Guest Form by entering

personal information: first name, last name, email, and company. It allows a customer to download needed

files without registering or logging in to an account.

On the other hand, it helps AMGS to track all configurator activities and recognize valuable ones in order

to target these users and potentially make business contact with them. Submitted forms are automatically

sent to the AMGS sales team, and once a week, AMGS also gets a report of all weekly configurator activities.

After the last sprint had been finished and verified by the customer, Helioz started with the

implementation. It included the solution’s implementation on a separate portal that supports a product

configurator and all other features applied during the project development.

It is actually a portal apart from the client's website, but because of the matching design, it ensures

seamless migration between the website and the portal so that end-users don’t even notice that they left

the original website and accessed the portal. This easiest and safest implementation type ensures that

the Helioz team can easily manage all future updates and potential issues.

Both teams did final testing at the end of the project journey, ensuring successful usage and

implementation of the features.

© 2022 Helioz Technologies